In the world of textiles, jacquard fabric has long been a symbol of sophistication, intricacy, and craftsmanship. Its complex, woven patterns, traditionally created on Jacquard looms, have graced everything from luxury upholstery to high-fashion garments. Among the various types of jacquard fabric, positioned jacquard fabric stands out as a distinct and innovative form of this timeless material.

Positioned jacquard is often used in textiles where the design is not only about visual aesthetics but also about enhancing the fabric’s functionality, such as in high-end home furnishings, fashion, or specialty fabrics for upholstery.

The process of producing positioned jacquard fabric involves the use of a Jacquard loom, a complex and sophisticated machine capable of weaving intricate patterns directly into the fabric. These looms use a series of punched cards (or modern computerized control systems) to control individual threads, allowing for the weaving of complex patterns and designs.

The first step in making positioned jacquard fabric is the creation of a custom design. The design is often created using computer-aided design (CAD) software, which allows designers to specify the pattern's size, location, and structure. Unlike traditional jacquard, where the pattern repeats continuously, positioned jacquard features patterns that are placed intentionally at specific intervals or positions across the fabric.

Once the design is finalized, it is translated into a program that controls the Jacquard loom. The loom uses individual threads controlled by hooks or mechanisms to weave the design. The positioned patterns are woven by adjusting the settings so that the design appears at designated spots, often in non-repetitive or asymmetrical arrangements.

The weaving process is the most intricate part, where the design is created directly into the fabric as it is being woven. The threads are lifted and lowered in specific sequences to create the desired pattern, and because jacquard fabric can be made with multiple types of yarns (such as silk, cotton, or synthetic fibers), the texture and sheen of the fabric can vary based on the materials used.

After weaving, the fabric may go through finishing processes such as dyeing, printing, or steaming to enhance its appearance, texture, and durability. For positioned jacquard fabric, the finishing process is particularly important to ensure that the designed patterns remain sharp and vibrant.

Positioned jacquard fabric’s unique ability to place patterns in specific positions gives it a wide range of applications across various industries. Some of the most notable uses include:

Positioned jacquard fabric is a favorite in luxury fashion and couture. Designers use this fabric to create garments with intricate, one-of-a-kind patterns placed in strategic areas. Whether in evening gowns, jackets, or scarves, positioned jacquard fabrics can add depth, elegance, and texture to clothing. The fabric’s ability to carry rich patterns in specific locations allows designers to create visual focal points, like highlighted sections of a garment or unique panel designs.

Positioned jacquard is commonly used in high-end upholstery, draperies, and bedding. The placement of patterns can enhance the visual appeal of home décor items by creating statement pieces, such as patterned cushions or accent chairs. In addition, the fabric’s durability and texture make it a great choice for items that need to withstand regular use while maintaining their aesthetic appeal. Positioned jacquard fabrics can also be used for custom-made furniture, where the pattern placement is critical to achieving a particular look.

In the bedding industry, positioned jacquard fabric is used for high-quality bed linens and duvet covers. The intricate patterns woven into the fabric enhance its luxurious feel, making it a sought-after material for premium bedding products. The fabric’s ability to be designed with specific placement allows for unique motifs, such as borders, medallions, or corner designs that elevate the overall aesthetic of the bed.

Another niche application of positioned jacquard fabric is in automotive interiors, where it can be used for seat upholstery, headliners, or door panels. The fabric’s ability to integrate structured patterns into specific areas of the car’s interior gives a customized look that is both functional and visually appealing. Automotive designers may use positioned jacquard to enhance certain features of the interior, creating a distinctive and cohesive design.

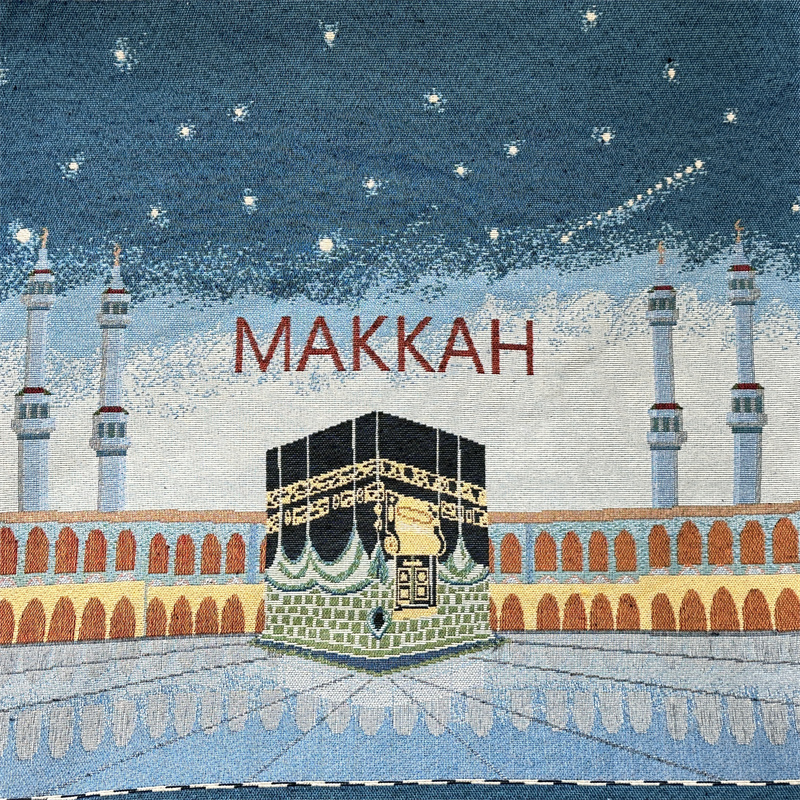

Positioned jacquard is also used in the creation of textile art, where the design can be more expressive or artistic. Artists and designers often experiment with different types of fibers and weave techniques to create fabric that serves as both a functional item and a work of art. Wall hangings, decorative throws, and custom textiles for exhibitions or installations frequently feature positioned jacquard to create a striking visual effect.

Positioned jacquard fabric offers several advantages, making it a preferred choice for certain applications:

The ability to position patterns exactly where needed gives positioned jacquard an edge in customization. This is particularly valuable for designers who want to create one-of-a-kind pieces or products that stand out from mass-produced textiles.

The intricacy and detailed nature of jacquard weaving give the fabric a sophisticated, luxurious feel. Positioned patterns enhance this visual appeal by allowing for design elements that are more personalized or strategic in placement.

Like traditional jacquard, positioned jacquard fabric is typically made from durable materials, making it resistant to wear and tear. It is also versatile enough to be used in a range of products, from high-fashion garments to home textiles.

The strategic placement of patterns creates dynamic, eye-catching designs that can bring life and elegance to any space or garment. This ability to control the placement of designs adds to the fabric’s ability to serve as a focal point in both interior design and fashion.

中文简体

中文简体 Español

Español